How To Remove Throttle Cable From Throttle Body

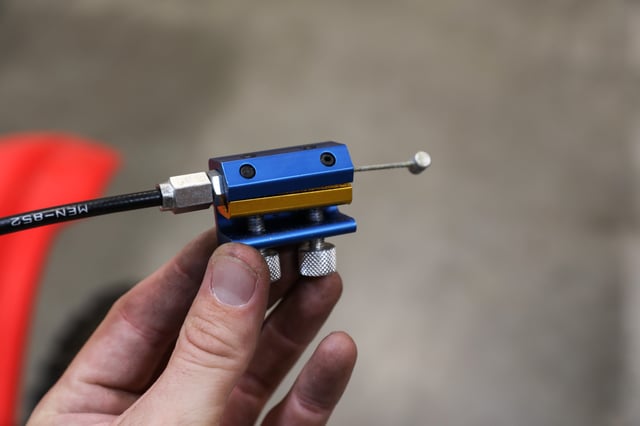

The throttle cable may seem similar a simple part of your bike, but it can proceed yous from riding if not properly maintained or replaced. Read as we accept you through cable maintenance and install tips for a new ProX throttle cable. With the riding flavor upon us, it'south not a bad time to cover an important, but often neglected, maintenance task: throttle cablevision inspection and replacement. The throttle cable connects your heed and body to the heart of your machine, which makes it an incredibly important link. Worn, damaged, misadjusted, or corroded throttle cables can pb to unsafe riding conditions and poor engine operation. Allow'south dive into tackling this common maintenance task. About service manuals suggest checking throttle functioning subsequently each race or every 2.5 hours of performance. Along with this generic recommendation, engine operation can also be an indicator of cablevision issues. Poor full throttle operation may exist a sign that the throttle cable has too much slack. An engine that is difficult to command or has an erratic idle may betoken that there is not enough throttle cable slack. Your service or owner's manual should provide all the pertinent cable adjustment information y'all need for your specific make/model of machine, and should exist used to complement the advice and recommendations provided in this write-upwards. Within the service manual, you should detect gratis play specifications, throttle cable routing information, lubrication info, and the prescribed tensioning process. We'll start by outlining the bones checks and adjustments that should be performed to ensure correct throttle cable performance. Once these are concluded, nosotros'll talk over complete cable replacement. Cable Status The throttle cable should exist visually inspected for damage. Cracks, kinks, corrosion, and severely worn areas due to rubbing should all be cause for business. Systematically inspect the cablevision from the throttle grip to the throttle body/carburetor as best as visually possible. Checking Cable Free Play Throttle cablevision free play is typically checked by measuring the corporeality of throttle grip movement relative to a stock-still point on the throttle cable housing. Most makes/models specify 2-3mm of throttle grip gratuitous play. This can easily be checked past referencing a predominant feature on the throttle grip, or marking it with a marker and measuring the amount of motion relative to the housing with a ruler, scale, or caliper. Checking Throttle Return All throttle systems designed for powersports applications are designed to fail closed in the event the throttle cables break or the rider loses control of the car. Return jump pressure can be inadequate if the throttle cables are sticky, bounden, or if the throttle grip is binding on accessories such as handguard mounts. Check throttle operation by fully opening the throttle and letting go. Ostend that the throttle quickly and easily returns completely to the closed position. Bank check throttle return with the handlebars all the way to the left, centered, to the correct, and halfway between center and full stop on each side. If the throttle does non completely return the cable may be binding, incorrectly routed, frayed, or corroded, which warrants farther investigation. Throttle Cable Adjustment About modern machines utilizing throttle bodies and carburetors apply 2 throttle cables, aptly identified as accelerator and decelerator cables. Older carbureted machines often only feature one throttle cable. Depending on the type of car you own, the adjustment process may differ slightly from the outline I'm going to provide. The number of adjustment locations volition also differ depending on the machine in question. Some applications have adjustment points at the throttle trunk or carburetor and at the throttle cable housing, while others accept a unmarried adjustment betoken on the throttle cable housing. On machines with multiple aligning points, minor adjustments are made at the throttle cable housing and major adjustments are taken care of on the throttle body/carburetor. Dual Cable Adjustment The starting time step to adjusting dual throttle cable machines is to remove any necessary dust covers and identify the accelerator and decelerator cables. The accelerator cable goes into tension when the throttle is twisted open and the decelerator cable is put in tension when the throttle is closed. Each cablevision is oftentimes easily identified visually by looking at the housing design or by making minor adjustments and determining what is affected. To adjust the cables, the locknuts are loosened and the cable adjusters are turned in to slacken or out to tension them. This can be achieved past mitt or with an appropriately sized wrench. Ordinarily, the decelerator cable is adjusted first. Decelerator cable tension is ordinarily gear up so that there is no play when the throttle grip is completely closed. Once the decelerator cable has been set, the accelerator cablevision is adjusted. The accelerator cable tension is usually fix so that 2-3mm of complimentary play is nowadays in the throttle grip. One time the correct tension has been applied, the lock nuts should be snugged and any dust covers should be slid back over the adjusters. Unmarried Cable Adjustment Single throttle cable aligning is straightforward. Any dust covers protecting the cablevision adjuster should be removed offset. Next, the locknut should exist loosened. The cable adjuster can then be adjusted in or out and so that the throttle grip has the right corporeality of complimentary play, which is usually two-3mm. One time complete, the locknut can exist snugged and grit embrace reinstalled. Checks After Adjustment Upon completion of any cable adjustments, the system should exist checked as outlined in the throttle render department of this commodity. Once y'all have confirmed that the throttle return functions properly in all handlebar positions, the engine should be started. With the engine idling and in neutral, rotate the handlebars from stop to end and heed for any changes in idle behavior. Increases or decreases in idle speed may suggest that the throttle cable is binding either due to tight spots or cable routing. Throttle Cable Replacement In the event that the throttle cable warrants replacement, cablevision replacement can exist accomplished fairly easily. Selecting and sourcing a new throttle cable is equally of import as carrying out the work. Sourcing OEM parts from a dealer tin can lead to overpaying, and then it's common for people to turn to the aftermarket. However, it'due south important to be careful not to cede quality for cost. ProX offers throttle cables made by OE manufacturers at affordable prices. Because they're made by OEM suppliers, OE quality and specifications are met. ProX throttle cables are made with pre-lubricated nylon inner sleeves, tightly-wound steel inner cables, and a flexible PVC outer jacket, which, combined, ensure shine cable operation and long life. Find ProX cables for your model here. The compages of your specific machine will largely dictate what must be removed in gild to successfully replace your throttle cablevision. Typically, the post-obit components will need to be removed: In one case the necessary components accept been removed, replacing the throttle cable is straightforward. We'll walk through the necessary steps with the assumption that we're working on a dual cable machine. The steps for a single cable application are nigh identical. Start by loosening the throttle cable adjusters on the throttle housing and slackening the cables. Adjacent, remove the fasteners holding the throttle cablevision housing together. Once removed from the handlebar remove the throttle cable ends from the throttle cable housing pulley. Notation the accelerator and decelerator cablevision positions. Remove any necessary covers from the throttle trunk or carburetor to gain access to the throttle cable ends. Note the locations of the accelerator and decelerator cables prior to removing them. Loosen the necessary lock nuts and adjusters then remove the cable ends from the pulley. On single cablevision carbureted applications featuring round or oval slide carburetors, unscrew the tiptop cap of the carburetor where the throttle cablevision enters the slide. Compress the return bound and advisedly remove whatsoever necessary hardware securing the cable finish to the slide. Once removed, the cable can be loosened and removed from the carburetor cap. Prepare the new throttle cables past applying cablevision lube to both ends of the cables. Check the smoothness of the cables by moving them back and forth prior to installation. Once the old throttle cables are costless on both ends, note how they take been routed. And so, remove the cables and route the new cables in a like mode. If the old cable routing is suspect, confirm with your service manual the factory prescribed cable routings. Upon successful cable routing, begin the reassembly process. First by installing the cable ends into the throttle body/carburetor and throttle cable housing. Turn the cablevision adjusters on the throttle grip housing all the way in, then turn each of them one turn out. Once this is done, unless otherwise specified, use the throttle body or carburetor adjustment features to have the majority of the slack out of the cables. Refer to the tips outlined in the cable tension adjustment section to correctly tension the throttle cables. After the cable tensions have been fix, be sure to cheque the functionality of the throttle render as prescribed previously. Once the new throttle cables have been installed and the return checks are consummate, finish the job by reinstalling any items that required removal to gain access to the cable system. With everything reinstalled, test the functionality of the organization kickoff with the engine off, then with the engine idling to ensure there are no abnormalities.

Topics: featured, Powersports, Tech

Written by

How To Remove Throttle Cable From Throttle Body,

Source: http://blog.pro-x.com/how-to-adjust-and-replace-your-motorcycles-throttle-cable

Posted by: griswoldbuturing1943.blogspot.com

0 Response to "How To Remove Throttle Cable From Throttle Body"

Post a Comment